By David Dodge, GreenEnergyFutures.ca

Three hundred million solar modules were installed around the world in 2020 and the number one question we hear at Green Energy Futures is what about solar recycling?

The problem with recycling solar modules is they are guaranteed to 20 to 25 years and are known to work for up to 40 years. In an industry that is really only about 10 years old, that’s quite a lag time.

There are a few start-up solar recyclers in Canada, but it’s still early days there.

There are about a dozen companies in the U.S. that call themselves solar recyclers, but only five are recognized by the Solar Energy Industry Association (SEIA) in the U.S.

We talked to Fabtech Solar Solutions based in Phoenix, Arizona. They started up about four years ago. They’ve found almost half of the solar modules they collect as waste can be refurbished and resold in an emerging used solar market. They’ve already refurbished and resold about 600,000 solar modules to homeowners, do-it-yourselfers, and van dwellers looking for affordable solar.

But this is only part of the story. While Fabtech specializes in extracting value out of refurbishing waste solar modules, there are other companies that specialize in recycling glass, metals, and other components.

Cascade Eco Minerals based in Medford, Oregon is a division of Dlubak Specialty Glass a company with a long history in the glass business.

“We’re really focused on end of life processing the glass because these modules tend to be 65 to 85% glass by weight,” says Chris Stearns, who used to work in the solar industry, but now is Cascade’s national sales director.

Cascade recycled 5.3 million pounds of glass or about 110,000 solar modules in 2020.

They’ve developed their own proprietary process for separating the layers and elements in a solar module with a goal of 100 recycling.

What’s in a solar module?

It turns out most of the materials in a solar module are pretty common:

- 65-70% glass

- 15% ferrous and nonferrous metals (aluminum and copper)

- 10% is encapsulant and back sheet

- 5% is solar cell material

The encapsulant is an ethylene-vinyl acetate (EVA) film that wraps the solar cells like a sandwich. But It is not ultraviolet resistant, so the glass provides this protection as well as protection against damage. Most solar modules are tougher than any roofing system with the possible exception of metal.

The actual solar cells are made of silicon, essentially sand, one of the most abundant materials on Earth. Once the silicon wafers are made each is coated with palladium or copper and each cell is connected using thin strips of tin-coated copper.

The frames are usually made of aluminum, comprising 15% of the module by weight.

These and the junction boxes and wires are quite easy to recycle.

And there are a few fly-by-night recyclers who recycle the easy stuff and then toss the rest in a landfill. This is a definite no-no. This could be why SEIA only recognizes five recyclers in the U.S.

Cascade Eco Minerals uses a proprietary process to separate the laminated parts and ensure no waste, toxic or otherwise goes to the landfill.

What about those nasty, toxic minerals?

The vast majority of the materials by weight are pretty common, but critics often point to nasty toxic materials as the Achilles heel of solar modules.

“It’s not something we want to ignore,” says Stearns. He says there are a few components that could be considered toxic.

“Primarily lead in the form of the solder that’s used to make the cell interconnections, but there are also heavy metals.”

“There’s an acronym: CIGS that … stands for copper indium gallium and selenium. And that material is sputtered onto the wafer material, the Silicon cell itself, to give it the electrical properties necessary to be an efficient solar cell,” says Stearns.

There are very small amounts of these minerals in a solar module, but if there are hundreds of thousands or millions of these modules sitting in landfills, then that is something to be really concerned about.

Proper recycling means none of these materials go to landfills and leach into groundwater.

About 91% of the solar market is dominated by crystalline silicon solar modules, the ones we are talking about here. Cascade Eco Minerals does not recycle thin-film solar modules most of which use cadmium telluride photovoltaic modules. First Solar, an American company dominates this market and offers its own recycling service.

The business of recycling

“We make money by taking a fee from the end-user,” says Stearns of Cascade Eco Minerals. In return, the companies get a ‘certificate of destruction confirming that the waste modules have been recycled and not dumped in a landfill.

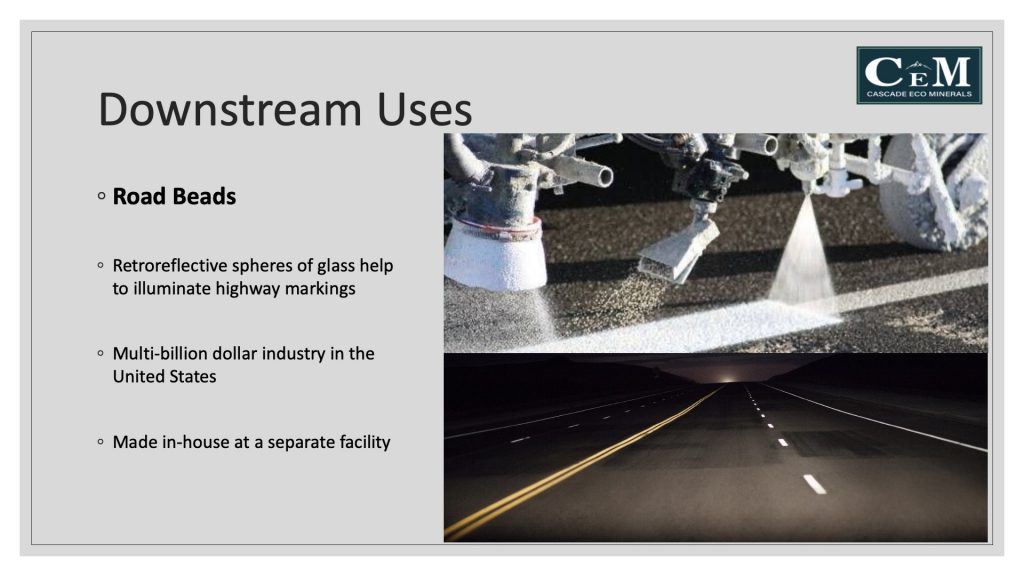

Cascade’s parent company reuses all the recycled glass and then Cascade sells the recovered aluminum, copper, and cell materials to other recyclers.

Stearns says Cascade operates on a “thin margin.” But that the long-term plan is to scale up and process hundreds of thousands or millions of modules. They hope to “Turn a profit that’s significant over time, but it’s going to be a process getting there.”

Meanwhile, it costs between $15 and $17 to recycle a solar module, a price some companies are paying but not all.

How do we stop the dumping of solar modules?

The solar industry does care about its image and is starting to work with companies like Fabtech and Cascade Eco Minerals, but how do we close the door on dumping.

Stearns says some modules are being dumped and others recycled, but “what we suspect is happening and it’s speculation because there really isn’t any data being collected, is that a lot of people are warehousing modules that are being decommissioned.”

Stearns speculates some may be hoping the cost of recycling will come down over time.

The European Union created the so-called “WEEE Directive” which has evolved into a form of Extended Producer Responsibility requiring the industry to collect waste solar modules. Washington State, California, and New York are all working on so-called take-back rules. Some advocates are also in favour of a deposit system for solar modules to collect funds to pay for end-of-life solutions.

Extended Producer Responsibility a Solution?

The movement to make producers responsible for their waste is growing in many sectors, but Stearns is not ready to give the idea blanket endorsement because of potential unintended consequences.

One consequence is losing business to other jurisdictions and then if the rules are poorly thought out “companies are imaginative in their ways of skirting around the issue.”

“I don’t know what the answer is,” says Stearns, but he points to Europe where the idea is to collect a deposit when you purchase a module. The funds then go towards end-of-life decommissioning and recycling.

“Something like this might be better accepted by module manufacturers that are now operating on razor-thin margins.”

The solar industry is just starting to come out of the wild west phase of evolution and companies like Fabtech Solar Solutions and Cascade Eco Minerals are working hard to do it right and make it affordable for the industry.

“I think it [solar] is going to be the energy source of the 21st century,” says Stearns. And this may already be true. Solar and wind power comprised 80% of all power generation projects built in the world in 2020 and is riding high with billions in investment.

With exponential growth in solar, the time to get recycling right is now. “My mother told me when I moved out, you buy a plunger before you need one,” says Stearns.

Here is a copy of Chris Stearns’ slide presentation that he uses to explain solar recycling and his company’s services. It explains the process and how solar recycling works.