By David Dodge, GreenEnergyFutures.ca

Momentum to build super energy efficient net-zero energy homes is growing, but what can you do about windows that are energy efficiency black holes?

Net-zero homes mimic the idea of the passive house by building super-insulated walls, sometimes up to 16 inches thick with an incredible insulation value of R50.

But then we use triple-paned windows that have insulation values of between R7 and R8. Don’t get me wrong, triple-paned windows are pretty awesome, but they are still by far the weakest link in green building design.

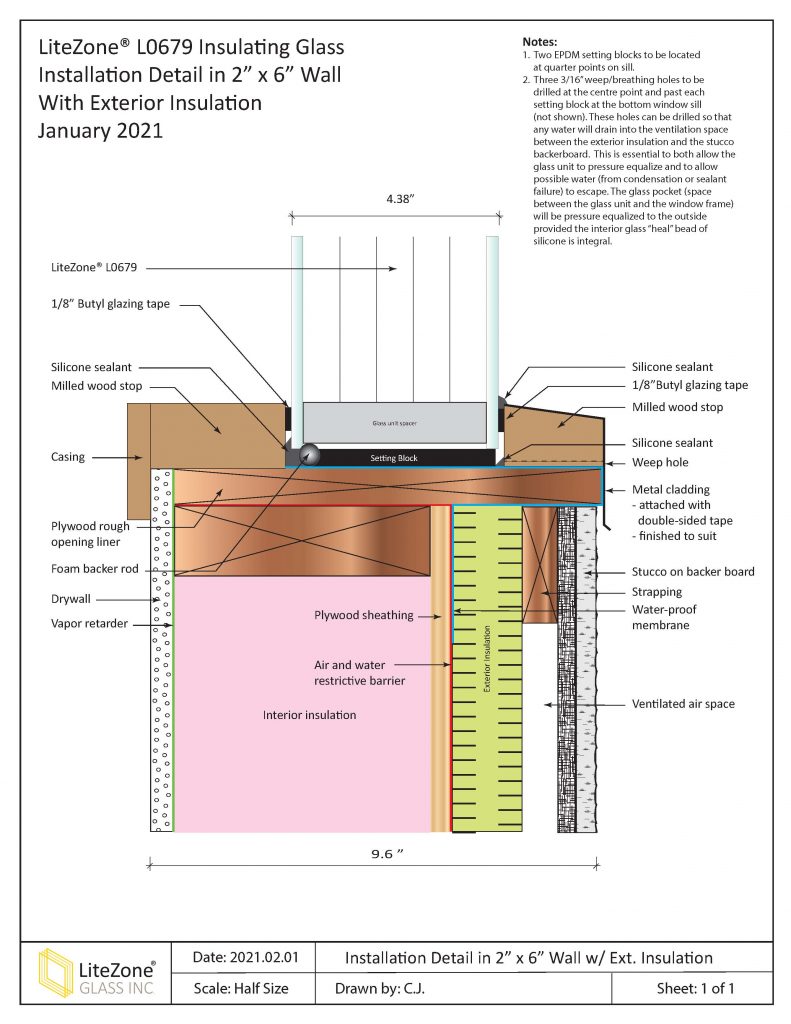

This troubled Greg Clarahan a great deal and after years of work his company LiteZone Glass has come up with a patented way of building multi-paned windows that have up to R22 insulation value.

That’s the equivalent of a 2×6 wall filled with insulation.

“LiteZone manufacturers a next-generation ultra-energy-efficient award-winning insulating glass unit that makes possible the world’s most energy-efficient windows,” says Clarahan from his plant in Edmonton.

“The goal of the development program for LiteZone Glass was twofold. One was to come up with a way of achieving unheard of insulating values, but in a way that was in harmony with nature and in harmony with physics so that the unit would also have a very, very long life,” says Clarahan.

Secret sauce of the super window

If we want better-insulated walls, we make them thicker and pack more insulation in them.

“The same idea is needed in order to solve the problem of the poor performance of the conventional insulating glass that’s on the market.”

After a great deal of research, he perfected the idea of creating very thick windows with multiple layers of film each with an insulating pocket of air.

“Now we can suspend between one and up to eight layers of film between two panes of glass and achieve a much, much thicker glass unit assembly that can achieve incredible insulating values,” says Clarahan.

This idea is so flexible you can create a window with one film between two panes of glass that mimics the performance of triple-paned windows, or you can go crazy and build a unit with eight films in between two panes of glass, is 7.5 inches thick and boasts an R22 insulation value centre of glass.

Multiple layers mean multiple Low-E coatings

It’s all about the number of layers, the spacing between the layers, and the number of low emissivity coatings (Low E coatings).

And since you have up to eight films you can add the coating to any or all the layers creating a super window.

“One problem with conventional glass is the inner gasses – the argon, or sometimes Krypton, or even Xenon – that they fill conventional insulating glass units with is that it is impossible to keep that gas in the glass unit,” says Clarahan.

The solution he found is to use plain old air and a patented method of equalizing the pressure in the glass unit. This, he says is all part of creating a product that will “last 60 years.”

As you might expect these windows can be a little more expensive, although Clarahan says their one film glass unit is comparable to triple-paned windows in terms of performance and price.

Six ‘paned’ units are best sellers

“The best-selling product is the one that has four suspended films right now,” says Clarahan. These windows work in renovations with 2×6 walls and feature R17 centre of glass and a rating of R14 for an overall window. You can think of them as six-paned windows, except that four of the panes are films.

I remember doing a story on the secrets of building net-zero with an engineer who installed quad-paned windows in his home and thinking wow that’s amazing. This takes windows to a whole new level.

This opens new possibilities in home design and radically improves the weakest link in the insulation of the building opening all sorts of new possibilities.

Frameless option = invest in more efficiency and less frame

“The best way to stop thermal transmission through a frame is to not have any frame at all,” says Clarahan. And that’s exactly what many of their customers are doing both on new buildings and renovation projects.

“It can be more economical as well because you eliminate the cost of the frame,” he says.

LiteZone does drop their glass units into fiberglass and wooden frames and has even found they can reuse frames from old windows if they are in good shape.

But going frameless means you avoid less efficient frames and you spend more of your scarce resources on a higher efficiency glass unit.

Rethinking Passive House Conventional Wisdom

Many of the traditionally designed net-zero and passive house homes we’ve covered in Green Energy Futures go to some lengths to harvest as much passive solar energy as possible. Such as the Grandin Green project where the south-facing wall of a beautiful net-zero home is covered with triple-paned glass that attempts to harvest as much passive solar energy as it can in the winter. In the summer this home has just the right shading to ensure the sun never shines on the south-facing windows.

“We have a different idea,” says Clarahan. “The better approach is to have a really high-performing window with very high insulating values and very, very low solar heat gain coefficient.” This way you are protected from heat in summer and your focus is on keeping heat in in the winter instead of trying to harvest unpredictable passive solar energy.

This way you can reduce your heating and cooling plant sizes. You don’t have to worry about trees and it simplifies your design allowing you to achieve your passive house energy budgets, he says.

Allan Gatenby and Janet Craig installed the four-film LiteZone units in their home. This took their windows from R2 to R14 and they really noticed the difference. Prior to the renovation, Craig said they had to keep their blinds closed all summer in their dining area to avoid overheating the space.

“We haven’t had our new blinds installed yet, and we have not felt any heat coming through these windows,” Craig says.

Gatenby was so impressed by these super windows he invested in the company.

Word is starting to get out

It’s been a long road for Greg Clarahan, developing and perfecting his idea to produce super windows. But the word is starting to get out.

LiteZone has opened a 20,000 square foot manufacturing plant in Edmonton, Alberta, Canada, and they have done all sorts of interesting projects.

“We replaced all of the glass in a high-rise residential tower in Edmonton and we’re in the process of replacing all the glass in the Port Theatre in Nanaimo B.C.”

They’ve provided glass units for renovation projects and new projects alike in Ontario, Alberta, Oregon, Montana, and Idaho.

And recently they replaced all of the glass in a heritage building in Ottawa where they reused the wooden frames in order to preserve the exterior aesthetics of the building. This heritage building now has R12 windows. Ottawa was so impressed they are doing the same seven other buildings.

This is a real game-changer for super-efficient homes and buildings. No longer does the glass unit need to be a gaping hole in the insulation of a building.

Green Energy Futures CKUA Audio Podcast