By David Dodge and Duncan Kinney

If you’ve ever gotten smoke in your eye around a campfire multiply that by the 2.7 billion people that still cook and heat their homes using open fires and leaky stoves.

And what is a temporary annoyance for you and me on a camping trip kills millions of people a year. Two million people a year die prematurely from illnesses attributable to indoor air pollution. More than one million a year die from chronic obstructive respiratory disease and nearly 50 per cent of pneumonia deaths among children under five are caused by children inhaling particulate matter from these fires (all numbers from the WHO).

Those are large numbers, too big to comprehend really but it gets worse. The soot created by these stoves is called black carbon and it is a powerful greenhouse gas. The deforestation caused by people cooking with wood on these inefficient fires doesn’t help climate change either. But there is a small scale, cheap solution that can be built using local materials that doesn’t emit as much pollution and drastically reduces the amount of biomass needed.

It’s called the rocket stove.

It’s a hyper efficient wood-burning stove that burns the biomass internally and at higher temperatures than a typical stove. Here’s a demonstration model built from recycled cans.

Ashley Lubyk next to a demonstration rocket stove used for cooking made from recycled cans.

But for Ianto Evans, a natural builder, architect and ecologist from Oregon in the United States who was involved in the development of the rocket stove, that wasn’t enough. He wanted to use the same ideas that were being put to use in the rocket stove for heating.

Enter the rocket mass heater.

With a couple of adaptations you get a heating appliance that can comfortably heat almost any space and use much less wood than a conventional wood burning stove. To learn more about them we headed down to Calgary to a workshop put on by Ashley Lubyk of Dirt Craft Natural Building and Rob Avis of Verge Permaculture. There were a dozen eager students learning how to build their own rocket crammed into a tiny garage.

“Well yeah, they’ve gone viral,” says Lubyk.

“They’re really appealing because they’re efficient, they convert the wood to heat very well and they’re also very effective… The other thing that appeals to a lot of people is that you can use coppiced wood or waste wood to heat with and they can be done very inexpensively and in a wide variety of applications.”

How rocket mass heaters work

Ashley Lubyk tends the fire on a half-completed rocket mass heater. This shows the combustion chamber before the barrel and thermal mass have been added.

The rocket mass heater will challenge your traditional pre-conception of a wood-burning stove. The wood is fed in vertically and the fire is contained. Here’s a half built one that they made to show us how it works.

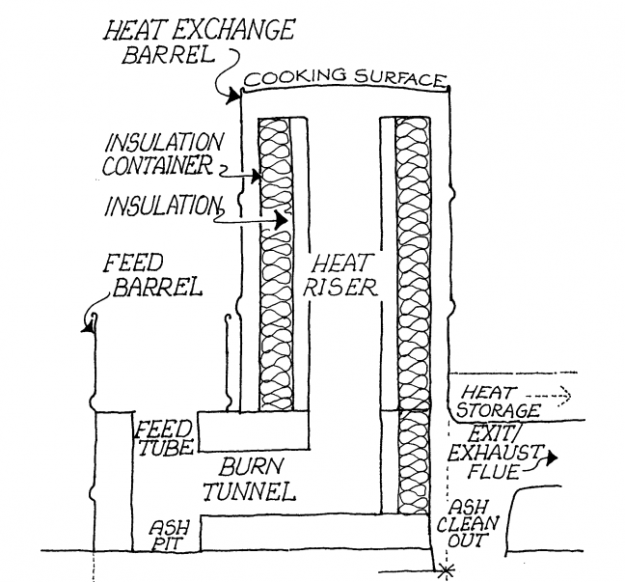

You can see the ends of the wood coming out of the burn chamber. Because the wood is fed in vertically only the tips burn, ensuring a proper air to fuel ratio. The flame then heads sideways and up then up the heat riser pipe. Another pipe insulated with perlite wraps around the heat riser ensuring the burn chamber remains hot and burns clean. Now here’s a completed version.

Now you can see that a metal barrel has been placed over the heat riser. The barrel contains the hot flue gases and ensures a clean, complete combustion. But here’s the genius part, those hot flue gases are then passed through a stove pipe that’s inlaid into a thermally massive cob bench. Cob is just sand, clay and water. That cob bench sucks up the heat from those hot flue gases and releases it over time. You’ve got a time-release heater that doubles as furniture.

Ashley Lubyk next to a completed rocket stove. Notice the barrel and the large cob bench he is sitting on. That cob bench acts as a thermal battery, storing the heat after the fire is burned out.

How efficient is a rocket mass heater? There are only anecdotal comparisons, but, Ianto Evans says in his book, Rocket Mass Heaters: Superefficient Woodstoves YOU Can Build, that when he switched from a small woodstove to a rocket mass heater he went from using four to five cords of wood per winter to about two thirds of a cord with a rocket mass heater.

“So with one of these stoves you’d typically burn it for three to four hours and then the bench, which is what we’re running the flue gases through before it leaves the building, will store that energy over that 3 to 4 hour burn cycle and release it for 12 to 72 hours depending on how cold it is outside,” says Avis.

Here’s a picture from Ianto Evans book that shows everything.

And it’s cheap like borscht. Do-it-yourselfers can build a rocket mass heater for between $200 to $400 depending on how of the materials you scrounge. All you need are refractory or fire bricks, regular brick, conventional oil and gas pipe cut to size, a large metal barrel, a large amount of clay and sand to make cob and a bunch of friends to help out.

And it’s not picky when it comes to what it will burn. Anything from willow, caragana, maple, construction waste, even pine cones. It thrives on burning skinnier sticks and as long the biomass being burned is seasoned, dry and will fit in the feed tube it will work.

Rocket stove potential

As for its use around the world numerous entrepreneurs and aid groups are figuring out how to get this technology out into the world. The original creators of the rocket stoves, the Aprovecho Institute, have a business arm called StoveTec which sells rocket stoves. The Paradigm Project is aiming to have five million of these stoves up and running by 2020.

Now, a rocket mass heater won’t be replacing your home furnace anytime soon. Changing CSA and fire codes isn’t a process that happens overnight. But there is a dedicated group of people in North America building rocket mass heaters for use in garages, outbuildings and cabins.

But it’s an odd case, a technology originally designed for the developing world is now making inroads in North America. Avis makes a persuasive case for not only the rocket mass heater but for the spread of low cost sustainable technology.

“Here is a technology, what I would call an appropriate technology, which is cost effective. It can be done by someone in their back yard and it doesn’t have to cost $15,000 to create a system that’s beneficial for the planet. Sustainability shouldn’t cost thousands and thousands of dollars, it should be accessible to a wide range of socio-economic classes.”